When you distill about 260 gallons of white whiskey a minute (un-aged whiskey), you need to have as much confidence in your process and ingredients as a train does in its tracks.

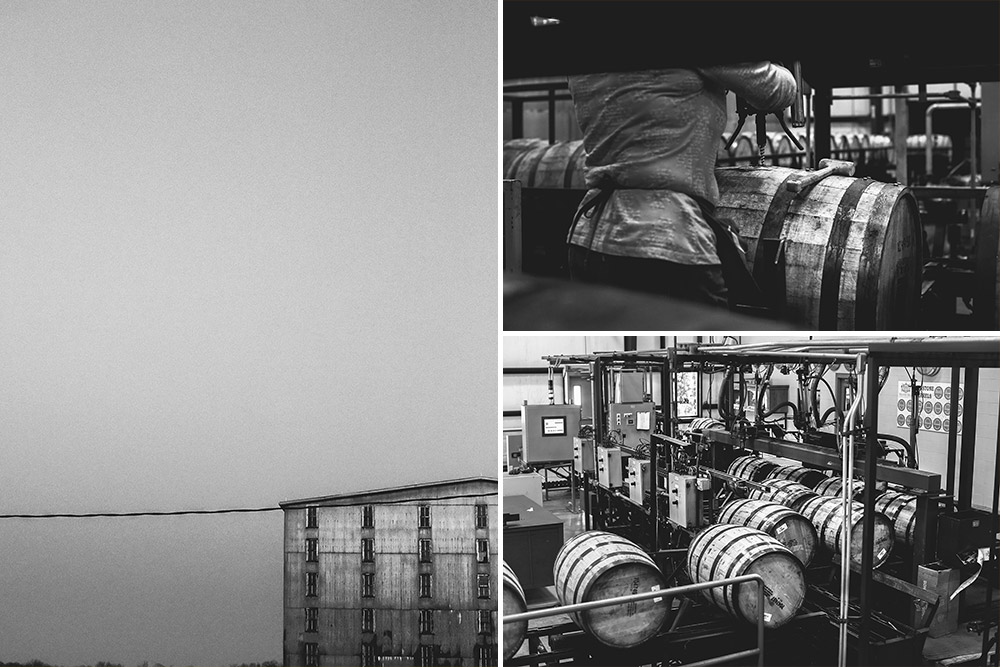

Founded in 1934, Heaven Hill is the largest family-owned and operated spirits producer in the US, lead in part by Master Distiller and Plant Manager, Denny Potter who joined in 2014. In addition to Denny’s 17 years of distilling experience, his contemporary view of the bourbon industry’s prevailing trends was critical to helping the business prepare for it’s next glacial-like evolution. Because in bourbon, what you do today will have a major impact on the business 8, 12, 20+ years from now based on barrel-aging schedules alone. Think about that — craft beer trends shift almost monthly by comparison.

Bourbon makers are also integral to other spirits industries, providing used bourbon barrels scotch, tequila, and rum producers all over the world. Most of the barrels are steamed and cleaned to neutralize any remaining bourbon character — they’re in essence just getting a used barrel as demand continues to surge for new white American oak barrels.

By contrast, brewers want the bourbon character left behind. When these things roll in to the Goose Island warehouse, there are often puddles of uncut bourbon left in them, sloshing around. Even the bone dry barrels will “sweat" during transport, and the bourbon suspended in the wood seeps out. The Goose crew often proofs this leftover whiskey down, pours it through a coffee strainer to filter out the wood shavings, and enjoys the perks of managing a massive barrel warehouse after hours. In industry’s like these, the rarest products are often enjoyed with the least amount of fanfare.

But that’s the extent of things in terms of preparation for Bourbon County Stout. In the barrel warehouse, they don’t steam the barrels or neutralize them — they just bottle up their share of the leftovers (the "brewers share” perhaps, after the angels and devils take theirs), top them up with BCS, and put them to bed. And when they start replacing all that air in the barrels with BCS, the smell that erupts from the barrels is exactly what you get hit with when you open up the doors to one of the Heaven Hill rickhouses — all that evaporating bourbon rushing toward the change in air pressure is enough to make you dizzy with delight.

And that’s what Denny loves about this whole thing. The barrels that he’s watched over for 8, 12, 20+ years get a second life and add to their pedigree, where their individual character will be expressed once again through the beer aging process. In that way, it’s not a used barrel he’s kicking out the door — it’s graduating to another life and going in to the hands of some friends up the road in Chicago.

Also, watching Denny nerd out over the quality of his locally sourced corn made me chuckle. This ingredient, often considered a subpar adjunct in beer-making, is so precious to the bourbon-making world. And here it is, technically a part of the BCS process — it’s just added a couple decades before mashing in.