Yuseff Cherney, Chief Operating Officer, Head Brewer and Co-founding Distiller of Ballast Point Brewing Company, leans forward in his office chair. “If you want to become relevant, then you're just the next guy jumping on the bandwagon. But if you are relevant your entire career, that is what it means to be ‘dedicated to the craft.’ And that is Ballast Point.”

Just to his left, Cherney looks out of a full-height glass window below to where Jack White, Ballast Point’s Founder and CEO, is on the brewery floor leading a tour group of about fifteen hop growers through Ballast Point’s new 150-barrel brewhouse installation at their Miramar location. Across his office is Colby Chandler, Ballast Point’s Vice President and Specialty Brewer. And just outside, the members of Ballast Point’s team occupy over eighty offices built into the common space above the Miramar tasting room and restaurant.

As the COO of one of the fastest growing breweries in the United States, Cherney’s office is situated in an ideal position to oversee the entire operation at a glance — and it’s no accident. Cherney’s been with the company since the beginning. He’s dealt with challenge and growth, both organic and planned. Along with the brewing-oriented leadership team of Jack White, Colby Chandler, James Murray, and others, he’s sought to keep the brand relevant, and more impressively, thriving.

During the past couple of years, we’ve witnessed some of craft beer’s best-positioned players expand aggressively with new equipment, new production breweries, and acquisitions through private equity, corporate buy-outs, and even deals involving one craft brewer acquiring another. But almost no one has expanded independently with the fervor and speed of Ballast Point. With few case studies to look to, the Ballast Point team is blazing a trail, and working to answer some hard questions along the way. How should growth happen? What does successful growth look like? How do you stay true to the vision?

Ballast Point’s success has taken place in San Diego County, one of the most densely populated craft beer markets in the country. Despite the number of breweries in operation, and beers available in the San Diego market, Ballast Point’s growth has a definitive hometown focus. Cherney acknowledges that the company might be “picky” about the markets it enters, but that is a deliberate decision. “Instead of filling a pipeline that quickly becomes full, we like the markets that want us — that come to us,” he explains. Rather than just looking at markets that can absorb an initial blitz and fill cold rooms, Cherney and the team look further out. “We focus on the throughput sales of the beer.”

“We want other people to make great beer. That’s the key to our growth as well”

Despite being available in about half the US, most states are a single city market for Ballast Point. It’s a slow, organic approach to growth in markets that demonstrate demand for beers like Wahoo, Longfin, Big Eye, Sculpin, Pale Ale, and Calico, and are able to maintain momentum. But with four locations in San Diego County, you can find Ballast Point’s beer almost everywhere in San Diego. For a brewery that produced over 71,000 barrels of beer in 2013, expanding at a 91% growth rate, it’s amazing to consider just how much beer Ballast Point sells in San Diego alone — nearly 40% (124,000 barrels) was consumed in their home market in 2014, which will adjust to about 30% in 2015 as they continue to grow in other markets.

It all started at a home brew shop. Jack White opened Home Brew Mart in Linda Vista in 1992. The reason was simple: White wanted to create a place where brewers could obtain ingredients and supplies, and share knowledge about brewing beer. At the time, Cherney was already established in the burgeoning San Diego beer scene teaching a brewing course at the University of California San Diego, alongside other industry pioneers like Chris White (who would later establish White Labs Yeast). Cherney was an avid homebrewer, and he would shop for ingredients at Home Brew Mart, one of the only two viable brewing supply stores in the county at the time.

One homebrew shop can change a city, and an industry. Cherney spent a lot of time at the Mart, engaging in conversations and answering other customers’ questions about supplies, processes, and ingredients. This got White curious and led to the simplest of introductions. “Who are you?” he finally asked, and the humble gateway to Ballast Point was opened. From the beginning, the vision was about teaching and learning through beer. It was about local homebrew clubs like QUAFF. It was about other industry suppliers, like White Labs, establishing their roots locally. And for many of the professionals in the area, it all goes back to Home Brew Mart.

But White had his eye set on a commercial operation from the beginning. Although it “took a few years,” White and Cherney opened the Ballast Point Brewing Company and the backroom brewery at Home Brew Mart together in 1996. “Homebrew Mart was the gateway,” Cherney says. “Once we added the brewery, it solidified us as the best homebrewing shop in San Diego. You could drink a beer while you shopped.”

Beers like Calico Amber Ale (winner of an absurd amount of awards over the years) and Sculpin India Pale Ale were born at Home Brew Mart. “Sculpin is an example of a homebrew recipe that went big,” says Colby Chandler, the man who wrote the recipe for Sculpin IPA, the beer that now comprises upwards of 55% of Ballast Point’s total sales. “But that is one of the awesome things about our lineup — every beer is a homebrew beer that went big.” Slowly, steadily, the brewery was occupying more and more physical space at Home Brew Mart. The company would need to go bigger.

“Sculpin is an example of a homebrew recipe that went big.”

Going big meant a new brewery for Ballast Point, and a second location in San Diego. In 2006, Ballast Point moved into their Scripps Ranch location in the north easters part of the city. This location enabled the brewery to increase production at a reasonable rate, mostly focused on meeting demand for San Diego. Today, it also houses Ballast Point’s award winning distilling operation (Ballast Point Spirits is a side project of Cherney’s, and it’s turning heads).

Over the years, Scripps Ranch evolved. In the back of the house, the production operation continued to grow in a mostly organized and deliberate fashion. At the same time, the front of the house took more of a “leaps and bounds” approach. In the beginning, there was a small standing-room-only, tasting room area, where folks would visit mostly to purchase kegs or packaged beer to-go. A complete re-design brought in a full-fledged hospitality space serving as a beer destination for locals and tourists alike. “We want to saturate San Diego,” Cherney says. “It is part of the growth strategy.”

In 2010, Ballast Point was named the World Beer Cup Small Brewing Company Champion Brewery. “It was a once in a lifetime achievement,” recalls Cherney. And by numbers alone, it’s easy to see Ballast Point harnessing the power of that recognition. Prior to the win in 2009, the company reported production levels of 11,293 barrels. In 2014, that number was 123,435 barrels — an order of magnitude in growth in just five years. Once again, Ballast Point’s growth meant looking for an additional home.

“It’s hard to find a rectangle to put a brewery,” says Cherney. Ballast Point learned some lessons from operating at the Scripps Ranch location, like the need to have a real ability for truck loading and the importance of logistics management. It was another northern suburb of San Diego, this time in Miramar, where Ballast Point found its most recent rectangle.

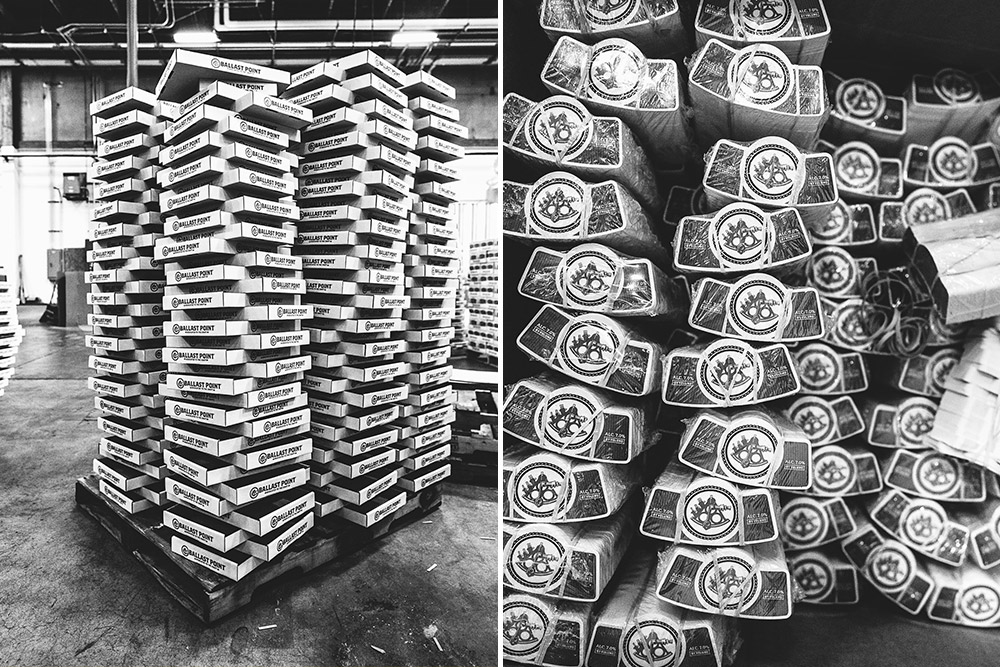

The 107,000 sq ft Miramar location houses an enormous tasting room, kitchen, and retail shop. But despite the seal of the front-of-the-house operation, this building is all about production at an incredible scale. A massive 15,000 sq ft coldbox occupies the back half, and is already subject to plans for expansion, doubling to 30,000 sq ft by the end of the year — itself larger than many start-up breweries. A truck loading bay is ideally situated about ten yards away from the door of the cooler, moving beer onto refrigerated trucks in seconds. A 150 barrel copper kettle brewing system sits in the brewhouse just on the other side of the taproom windows flanked by canning and bottling lines that run at a ferocious rate.

The capacity at Miramar is probably more than White, Cherney, and Chandler could ever have dreamed as they sipped on hoppy beers in the back of their homebrew store in the mid-1990s. But growth has lead Ballast Point to a unique time and place in brewing history. But with so much work to do to keep a multi-site operation humming along, one could forgive them for not resting on their laurels. “Our plan is to drop two more 750 barrel fermenters in each month until we run out of space,” says Chandler, pointing down the row of stainless steel tanks outside in back of the facility. “See, they must have just poured the concrete on the end of the pad.” As he climbs around the mass of steel, Colby points out that the pad is six feet deep of pure rock. The concrete pad will provide some ballast, if you will, for the literal weight of their growth.

Scale is a funny thing in this industry. At Home Brew Mart you can still buy hops by the ounce. At Miramar, Chandler gleefully proclaims “We literally dry hop with close to a ton of hops on beers like Sculpin. It’s kind of crazy, but pretty awesome, when you think about it.”

Growth is a science. Chandler notes that the future of the industry will respond to growth in different ways. “The pendulum will be swinging.” he explains. “There will be a handful of mid-size and regional breweries that will thrive by making really good beer. We’ll also see a brewery in every little town, servicing a tight radius of beer drinkers.” We might be at a point in this industry where the opportunity for growth at the level of a Ballast Point seems non-existent to some, but the lesson about great beer will ring true for many. “We want other people to make great beer. That’s the key to our growth as well,” Cherney adds.

But brewing great beer and financing growth aren’t always simpatico. In an industry wrestling with the realities of buy-outs and investments driven by short-term returns, a model like Ballast Point’s can seem incredibly risky, or critical depending on your point of view. For Ballast Point, financing comes from two key sources: internal reinvestment into the company and healthy partnerships with sources who do not demand a controlling interest in how things are done. To this day, White remains a majority owner of the company, which enables him to ensure that the company continues to invest in his brewer-first philosophy. “We have provided about 25% of the expansion funding,” explains Chandler, “with the other 75% coming from our banking partner, who has been great to work with.”

You don’t take on that kind of debt without being a little scrappy first. “We’re big fans of repurposing used equipment,” Chandler says, “which thankfully lead to us fulfilling the dream of being part of the copper top club with the brewhouse we pulled out of Lohr, Germany.” Used equipment hasn’t been on the market in a substantial way for years, meaning that securing it can be tricky. But in the end, it’s worth the effort if it means you’re not waiting on a brand-new Chinese-manufactured brewhouse that gets delivered with rust spots that need to be welded over.

Efficiencies at this scale are also critical. Take for example, sourcing raw ingredients. Not only are brewers using exponentially more hops per barrel of beer than ever before (in the midst of an ongoing shortage), but the same goes true for pounds of malt per barrel. “Raw ingredients are an issue no matter how fast you’re growing,” says Chandler. “We’ve spent many days sourcing ingredients to feed our growth, looking at alternative methods to get those raw ingredients, and looking for creative ways to increase efficiencies from the ingredients that we’ve already contracted.”

But perhaps none of this has been as crucial to Ballast Point’s growth as the investment in their labs. Ballast Point employs roughly five full-time employees to manage its quality control and quality assurance programs across the various locations. The goal is to brew, package, and sell “the most consistent beer that’s out there,” says Cherney. With the help of a serious sensory panel program, blind tasting trials, state-of-the-art equipment, and trained chemists who have a passion for beer, Ballast Point has succeed in getting beers like Sculpin into package and into target markets as far away as Tokyo. And they know exactly how low to get their dissolved oxygen levels in order to ensure a perfect ending to such an epic journey.